Voltage regulators are important components in industrial automation because they ensure that electronic systems operate steadily and have constant voltages. In an industrial setting, which is always filled with complex equipment, precision, and reliability must be present and hence forms a more significant concern in voltage regulation. Voltage regulators can regulate input fluctuations of voltages as well as give out a stabilized output voltage. They guard against sensitive equipment. It basically contributes to having an efficient overall system. In this blog , we will explore the different types of voltage regulators; their working principles; and its application in industrial automation.

What is Voltage Regulation?

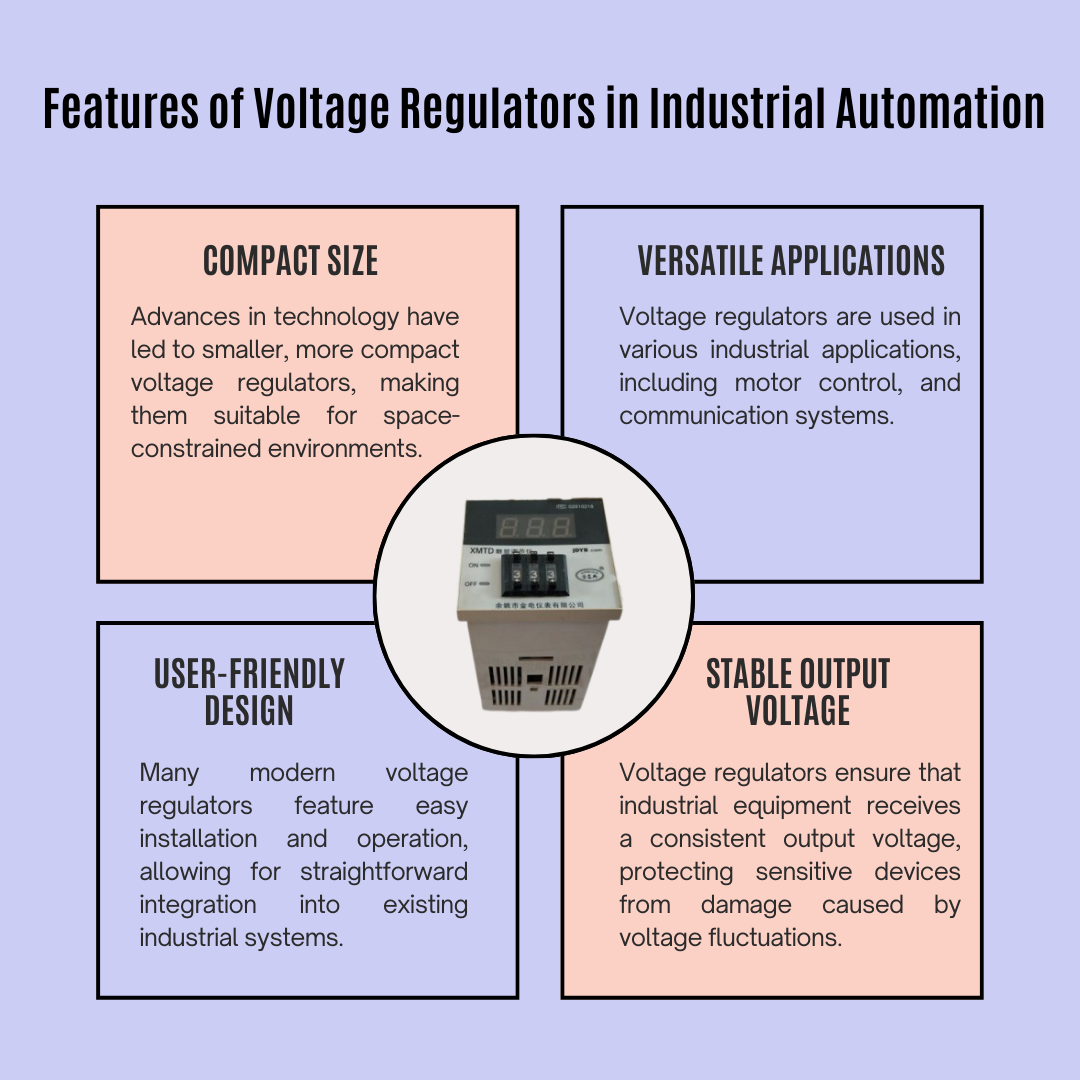

Voltage regulation is the method of keeping an output voltage uniform when the input voltage is varying or the conditions of the load are also changing. Change in power supply or the condition desired by loads and environmental may cause the fluctuation of voltage in industrial automation. These types of variation may cause a malfunction in equipment, reduction in efficiency, or even damage. Such type of electronic devices, which automatically regulate the voltage, thereby maintaining a stable output, is absolutely vital for the proper working of a system.

Importance of Voltage Regulation in Industrial Automation

Voltage regulation ensures that a voltage regulator maintains a smooth, uninterrupted process of industrial automation. Voltage spikes or drops may cause the failure of a system, high-priced shutdown, or damage a piece of equipment by disrupting sensitive electronic components' performance. Therefore, voltage regulators maintain the voltage at a specified range to prevent these problems and result in industrial systems running reliably and at maximum efficiency.

Working Principle of Voltage Regulators

Linear voltage regulators adjust the input voltage to provide a stable output. The change in the input voltage or load conditions does not affect the output voltage.

There are various types of voltage regulators, each based on different working principles.

- linear regulators: The linear regulators have the ability to continuously regulate excess voltage as heat at a steady output voltage. Even though they are simple, cheap and provide smooth voltage regulation, they are less efficient compared to other regulators. Where the efficiency of the regulator is not an issue but the input voltage is close to the desired output value, linear regulators will be more than adequate.

- Switching Voltage Regulators: They have advantages over linear regulators. For instance, switching regulators utilize input voltage to switch electronic components on and off fast to convert a high input voltage into a lower output voltage. In reality, these regulators apply inductors, capacitors, and other circuit elements in storing and releasing energy and therefore provide a stable output voltage while minimizing power loss. Hence switching regulators are more suitable for use in applications requiring a high degree of efficiency and where the input voltage and the output voltage are significantly different.

Types of Voltage Regulators

Voltage regulators come in numerous types, which differ from one another in application and purposes in industrial automation. The two fundamental types include linear and switching, while subcategories exist for both types.

1. Linear Voltage Regulators

They are simple, dissipating the excess input voltage in the form of heat and offer relatively stable output voltage. Normally used in low-power applications wherever simplicity and smooth voltage regulation are important and not too much so with respect to efficiency.

- Series Regulator: A type of linear voltage regulator, which uses a series pass element to control the output voltage generally a transistor. In this configuration, the resistance of the element is varied to keep output voltage essentially constant.

- Shunt Regulator: The regulator here takes off the excess current that has to be diverted away from the load for maintaining the voltage. Shunt regulators are fewer, but they find application in specific low-current applications.

2. Switching Voltage Regulators

Switching regulators are much more efficient and are used widely in applications where power is high and energy loss has to be kept to its minimum levels. They use high-speed switching to regulate the output voltage and find particular application in high-voltage differences.

- Buck Regulator: A switching regulator that steps down or decreases the input voltage to a relatively low output voltage. Its application in industrial automation is very prevalent as it converts the high supply voltage to lower levels required by electronic circuits.

- Boost Regulator: Here, in the boost regulator, the input voltage is increased to a higher level as its output voltage. The application of this boost regulator is basically there in the case where the input voltage is lesser than the output voltage in an application.

- Buck-Boost Regulator: This takes the input voltage and steps it either up or down to produce the desired output. It is highly adaptable and used in applications where the input voltage floats above or below the required output.

3. Automatic Voltage Regulators (AVR)

A live automatic voltage regulator always provides a constant and appropriate output level of voltage. These devices are often applied in industrial automation because they regulate the voltage of important equipment so that such can be protected from voltage spikes, drops, or fluctuations. AVRs can accept a broad range of variations in input voltages so they are best for keeping the voltage stable in environments which employ unreliable power supplies.

Applications of Voltage Regulators in Industrial Automation

Voltage regulators are important in industrial automation, wheVoltage regulators come in various types, which differ from one another in application and purposes in industrial automation. The two fundamental types include linear and switching, while subcategories exist for both types.

1. Linear Voltage Regulators

They are simple, dissipating the excess input voltage in the form of heat and offer relatively stable output voltage. Normally used in low-power applications wherever simplicity and smooth voltage regulation are important and not too much so with respect to efficiency.

- Series Regulator: A type of linear voltage regulator, which uses a series pass element to control the output voltage generally a transistor. In this configuration, the resistance of the element is varied to keep output voltage essentially constant.

- Shunt Regulator: The regulator here takes off the excess current that has to be diverted away from the load for maintaining the voltage. Shunt regulators are fewer, but they find application in specific low-current applications.

2. Switching Voltage Regulators

Switching regulators are much more efficient and are used widely in applications where power is high and energy loss has to be kept to its minimum levels. They use high-speed switching to regulate the output voltage and find particular application in high-voltage differences.

- Buck Regulator: A switching regulator that steps down or decreases the input voltage to a relatively low output voltage. Its application in industrial automation is very prevalent as it converts the high supply voltage to lower levels required by electronic circuits.

- Boost Regulator: Here, in the boost regulator, the input voltage is increased to a higher level as its output voltage. The application of this boost regulator is basically there in the case where the input voltage is lesser than the output voltage in an application.

- Buck-Boost Regulator: This takes the input voltage and steps it either up or down to produce the desired output. It is highly adaptable and used in applications where the input voltage floats above or below the required output.

3. Automatic Voltage Regulators (AVR)

A live automatic voltage regulator always provides a constant and appropriate output level of voltage. These devices are often applied in industrial automation because they regulate the voltage of important equipment so that such can be protected from voltage spikes, drops, or fluctuations. AVRs can accept a broad range of variations in input voltages so they are best for keeping the voltage stable in environments which employ unreliable power supplies.

re precision, reliability, and safety are paramount. Here are some key applications:

- Power Supply Systems:Voltage regulators are critical in power supply systems to ensure that equipment receives a stable and consistent voltage. This prevents damage from voltage fluctuations, which can cause system failures or reduce the lifespan of industrial machinery.

- Motor Control: In motor control applications, maintaining a steady voltage is essential for smooth operation. Voltage regulators ensure that motors operate within the correct voltage range, improving efficiency and reducing wear and tear on components.

- Automation Controllers:Automation controllers, which manage complex industrial processes, rely on regulated voltage for accurate data processing and communication. Voltage regulators provide the necessary voltage stability, ensuring reliable and efficient control of automated systems.

- Communication Systems: Industrial automation often involves communication networks between machines and control systems. Voltage regulators are used to maintain the voltage levels required for uninterrupted communication, preventing signal loss or interference due to voltage variations.

- Safety Systems: Safety systems, such as emergency shutoff devices, rely on voltage regulators to function correctly. A stable voltage is essential to ensure that these critical systems operate without failure in case of emergencies.

Limitations of Voltage Regulators

While voltage regulators play a critical role in industrial automation, they do have some limitations:

1. Efficiency: Linear voltage regulators are less efficient, especially when there is a significant difference between input and output voltage. They dissipate excess voltage as heat, leading to energy loss and the need for heat management solutions, such as heat sinks or cooling systems.

2. Complexity: Switching regulators are more efficient but are also more complex to design and implement. They require additional components, such as inductors and capacitors, which can increase the cost and complexity of the system.

3. Voltage Drop: In some cases, voltage regulators may introduce a slight voltage drop, meaning the output voltage is slightly lower than the desired level. This can affect the performance of sensitive equipment in certain industrial applications.

4. Noise Generation: Switching regulators, while efficient, can generate electrical noise due to the rapid switching of components. This noise can interfere with other electronic systems, requiring the use of additional filters to minimize interference.

How Voltage Regulators Work in Industrial Automation

Voltage regulators work by constantly monitoring the input voltage and adjusting their internal components to maintain a stable output voltage. In industrial automation, this is particularly important for ensuring that equipment operates within its specified voltage range, regardless of changes in input voltage or load conditions.

- Series Regulator in Industrial Automation: A series regulator, a type of linear regulator, is commonly used in industrial automation to maintain a constant output voltage. It works by varying the resistance of a series pass transistor, controlling the flow of current and stabilizing the output voltage.

- Switching Regulator in Industrial Automation: Switching regulators are more commonly used in high-power industrial applications because of their efficiency. By rapidly switching components on and off, they minimize energy loss and provide a consistent voltage output, even when the input voltage fluctuates significantly.

Selecting the Right Voltage Regulator for Industrial Automation

Choosing the appropriate voltage regulator for industrial automation depends on several factors, including the input and output voltage, efficiency requirements, and the specific application. Here are some key considerations:

- Input Voltage Range: Ensure that the regulator can handle the full range of input voltages without affecting the stability of the output voltage.

- Output Voltage Requirements: Select a regulator that can maintain the desired output voltage, even under varying load conditions.

- Efficiency: If energy efficiency is a priority, switching regulators may be a better choice than linear regulators, especially in high-power applications.

- Noise Tolerance: Consider the level of electrical noise generated by switching regulators and whether additional filtering will be required.

Voltage regulators are essential components in industrial automation, ensuring that equipment receives a consistent and stable voltage, even when the input voltage or load conditions change. By maintaining a steady output voltage, voltage regulators protect sensitive components, enhance system efficiency, and prevent costly downtime. Understanding the different types of voltage regulators, their working principles, and their applications in industrial automation is crucial for selecting the right regulator for your needs.

Whether it’s a linear voltage regulator providing simplicity and smooth voltage regulation, or a switching regulator offering high efficiency, voltage regulators play a crucial role in maintaining the stability and reliability of industrial automation systems.

Validate your login

Sign In

Create New Account