Solenoid valves are crucial to the marine automation industry as they are a core component in many control and regulating systems across a wide range of applications on a marine vessel. Considering fluid management and even engine controls, these are purely electromechanical devices that allow safe and efficient operations of all marine systems. This blog shall outline the necessity of solenoid valves in reliable marine automation and consider their role, kinds, application, and principle of work, showing how all these contribute to a successful marine system.

Understanding Solenoid Valves in Marine Automation

What Is a Solenoid Valve?

This is the type of valve, that is electromechanical which operates on the regulation of flow of fluids or gases within a system. There are two major components involved here: the valve body and the solenoid coil. When energized with a solenoid coil, it forms a magnetic field. So in one case, the valve would be opened up while on other cases, the valve gets closed. Therefore, a simple mechanism becomes really powerful for solenoid valves to work exactly while the flow of fluid or gases.

Role of Solenoid Valves in Marine Automation

Solenoid valves control the flow of water, fuel, lubricants, and gases in marine automation. Their application allows for precise flow control in cooling, propulsion, and even power generation systems to operate within design parameters. Whether it be the correct amount of fuel reaching the engine or a hydraulic system maintaining its prescribed pressure, solenoids are a critical component.

Importance of Solenoid Valves in Marine Automation

The importance of solenoid valves in marine automation cannot be overstated. This is because solenoid valves are the best tools for controlling fluid and gas flow with precise accuracy in marine systems where high reliability and efficiency are demanded. In addition, solenoid valves possess a host of benefits such as quick response times, ease of integration with control systems, and operation in the harshest marine conditions.

Solenoid Valve Applications in Marine Systems

Solenoid valves are used in a wide variety of marine applications, from cooling systems for engines to fuel management. Its versatility and high accuracy make the product ideal for both pneumatic and hydraulic systems. Among the most common uses of solenoid valves in marine automation are the following:

- Fuel Management Systems: Solenoid valves are used to control the fuel flow in marine vessels. They maintain a desired amount of fuel delivered to the engine. In this manner, the engine performs optimally without wasting resources, and emissions are minimized as well.

- Engine Cooling Systems: For every marine vessel, cooling engines is highly crucial in sustaining low temperatures from inside the ranges within which safety can be sustained. Controlling the flowing coolant is done by a solenoid valve. It decides whether adequate cooling is brought to an engine. The energization's presence leads to opening from the side of the solenoid valve bringing coolant and letting it run through an engine. The absence of energization provides closure of that valve thus halting the movement of flowing coolant.

- Hydraulic and Pneumatic Systems:Solenoids also control the hydraulic and pneumatic fluids in marine systems. In hydraulic machinery, such as cranes, winches, and steering systems, these valves regulate pressure and fluid flow. In pneumatic systems, solenoid valves regulate air flow that is required for operations, thus achieving total equipment control.

- Ballast and Ballast Water Systems:Solenoid valves are often used to control ballast water in many marine vessels to modify their weight and stability. Solenoid valves allow the safe operation of vessels as they precisely regulate the flow of water entering and exiting the ballast tanks.

Types of Solenoid Valves Used in Marine Automation

Depending on the design or the kind of function of the operation, different application or environment solenoid valves differ. For instance, the types include the direct-acting kind that the marine automation system applies to.

- Direct-Acting Solenoid Valves: A direct-acting solenoid valve acts directly when its solenoid coil is energized. Direct-acting valved application is suitable for situations requiring immediate response or precise control. Solenoid valves used in marine applications to control fuel flow or coolants.

- Normally Closed and Normally Open Solenoid Valves:These solenoid valves are available in normally open or normally closed configurations, depending on the application. A normally closed solenoid valve will close when the solenoid is not energized, whereas a normally open valve will permit flow when the solenoid is de-energized. These valves are widely used in marine applications where precise flow control is critical.

- Pneumatic Solenoid Valves: In marine automation, pneumatic solenoid valves are used to control the flow of compressed air. They can be applied for operating air-driven equipment such as pneumatic actuators.

- Hydraulic Solenoid Valves: Hydraulic solenoid valves have been integrated to regulate hydraulic fluid movement in marine machineries. These control valves come in handy controlling power supply and hydraulic operations in large merchant vessels. In this operation, they control the constant flow and pressure at demanding conditions.

- Gas Solenoid Valves:A gas solenoid valve is a device that controls the flow of gas in a marine system, in particular, for fuel gas or compressed air. Gas-powered engines and safety systems which use gas in releasing certain action also utilize main solenoids for their system.

The Working Principle of Solenoid Valves

Solenoid valvesoperate on the simple, effective principle of an electromechanical mechanism. At the core of a solenoid valve is a coil that, once energized, develops a magnetic field which acts on a valve mechanism to close or open a valve. The solenoid energizes and pulls a plunger or armature inside the valve body, opening the valve to allow fluid or gas flow. When the solenoid is not energized, the valve is closed, and flow is stopped. This action enables solenoid valves to control the flow of fluids and gases in various automation systems.

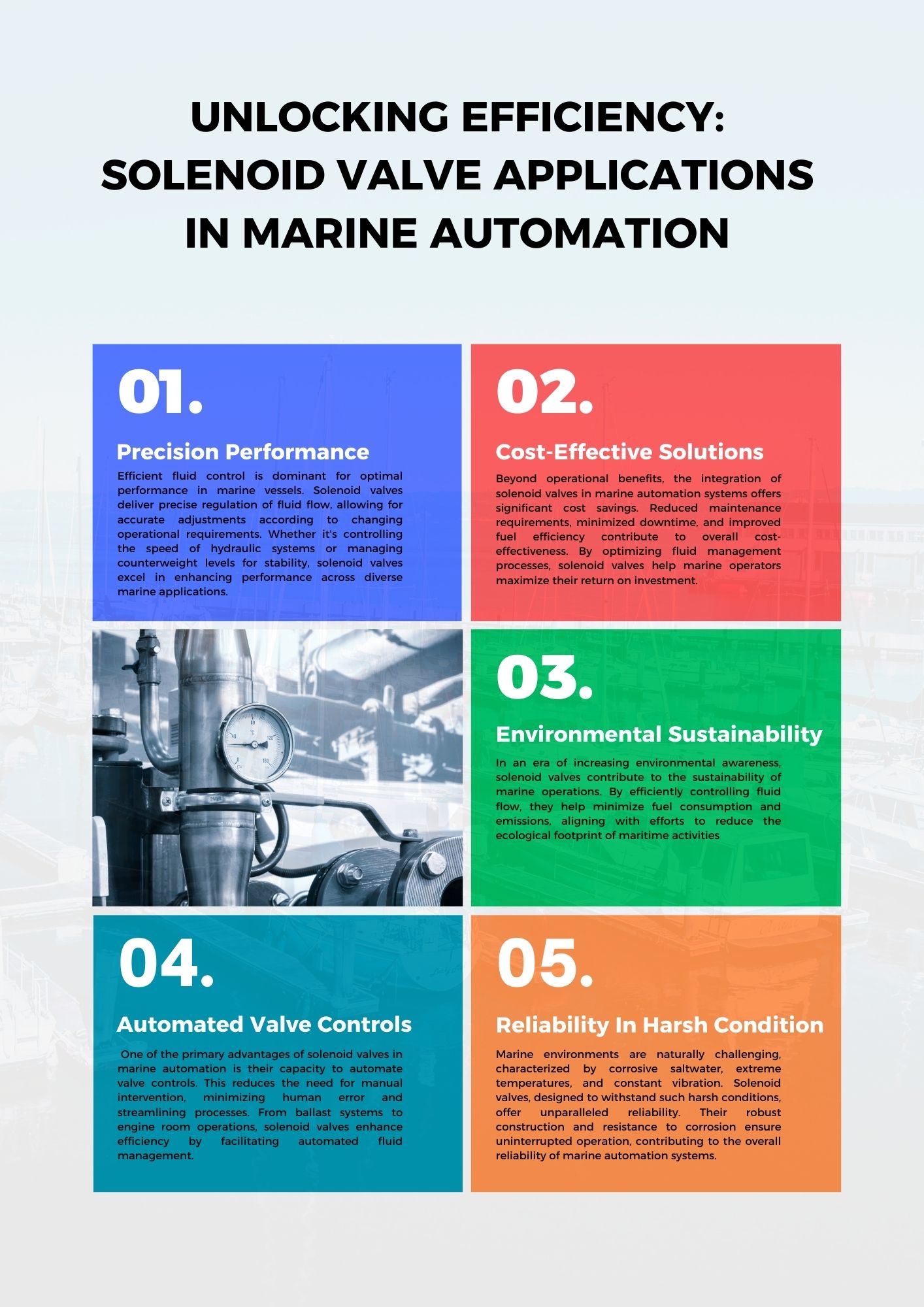

Solenoid Valve Advantages in Marine Automation

Solenoid valves are an important component in marine automation since they provide several key benefits as discussed below:

- Fast and Precise Control: A solenoid valve will open or close nearly immediately once the solenoid is energized or de-energized. This means that solenoid valves provide fast and precise control over fluids and gases flowing in a marine system. This is necessary for any marine system, for both safety and efficiency purposes.

- Durability in Harsh Marine Environments: Marine environments are severe for equipment with saltwater, high humidity, and excessive temperature changes. Solenoid valves are designed to satisfy these extreme requirements, which makes them excellent components for marine automation systems.

- Energy Efficiency:Since the solenoid valves are electrically operated, they can be integrated into automation systems to provide energy-efficient operation. When energized, the solenoid valve draws very little power; when not in use, it draws no power. This means that overall power consumption in marine automation systems is reduced.

- Simple Integration with Control Systems:Solenoid valves can be easily incorporated into marine vessel control systems to enable fluid and gas flow to easily be managed and monitored by operators from a distance. The overall efficiency and safety of the system of marine automation systems are enhanced because it offers real-time feedback for control.

- Reliability and Safety: Solenoid valves are highly accurate in operations, and they ensure there is no inconsistency in system performance, thereby reducing failures or malfunctions. Thus, in the critical use of marine applications, including engine cooling or fuel management, solenoid valves ensure that the system remains safe and reliable in all the operating conditions.

Maintenance and Troubleshooting of Solenoid Valves in Marine Automation

Although solenoid valves are designed to be very durable and reliable, there is still the requirement of routine maintenance for good operation. Some common solenoid valve maintenance jobs on marine automation systems are the following:

- Checking of the solenoid coil for wear or damage

- Cleaning the valve body, checking if there is some obstruction or debris in it which could impair valve working.

- Test the valve operation periodically for proper opening and closing with energized/de-energized solenoid operation.

- Leak check around valve seals. Proper sealing is ensured in order not to allow leakage of fluid or gas.

In case of a failure, solenoid valves often get repaired by replacing the damaged components like the damaged solenoid coil or valve seals. The correct functioning of a valve has been lost because of either malfunctioning of the solenoid coil or valve blockage or actuator mechanism damage.

Solenoid valves are essential components for marine automation due to their accurate control, reliability, and durability in hostile marine environments. From fuel management to hydraulic systems, these valves are applied in a wide variety of marine applications for smooth operations and safety onboard. Whether controlling the flow of fuel, cooling fluids, or gases, solenoid valves are indispensable in optimizing performance and efficiency in marine vessels. Importance and Maintenance: Knowing the importance and maintenance of their equipment will help marine operators to make their systems run efficiently and safely. In this way, long-term success in marine automation will be assured.

Validate your login

Sign In

Create New Account