Industrial automation is revolutionizing modern manufacturing and process industries at a rapid pace. Advanced automation results in an increase in complex and reliable component dependencies for systems to operate satisfactorily. Among such key components is cables, adapters, and industrial networking equipment, all of which play critical roles in the functioning and reliability of automation systems. This blog is going to explore the importance of reliable adapters in industrial automation and what they add up to for overall efficiency, productivity, and safety in modern automation systems.

The Role of Adapters in Industrial Automation

Industrial automation refers to the use of technology to automatically perform tasks with little or no direct human involvement. It covers a very broad spectrum-from simple mechanical operations to complicated control systems that change the production phase in real-time. A crucial part of such systems involves adapters, helping ensure proper communication between such devices as sensors, controllers, and actuators.

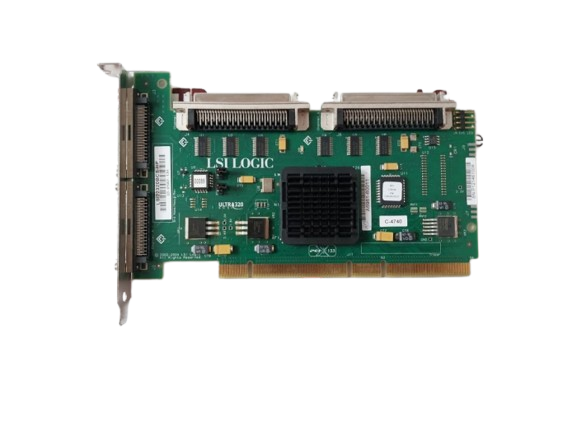

Adapters essentially are interfaces making it relatively easy to connect cables and components smoothly into an industrial network. For sure, the possibility of reliable delivery is where data transfer and power supply from one device to another come in. And the environment might be demanding, but without a reliable adapter, industrial automation systems should be able to fail in times and thus trigger downtime and possible system failure.

Why Reliability Matters in Industrial Applications

Reliability, in the case of industrial automation, is too important to emphasize. Appliances that fail or break would greatly hamper production, lower productivity, and even incur hefty maintenance costs. Manufacturing, oil and gas, food, among others, all depend on the steady production line with continuous flows for the proper functioning of their systems. Therefore, they need every module of their automation system to be reliable for there to be no down time and avoid additional unnecessary expenses.

Adapters must then be designed to tolerate the extreme conditions of industrial spaces. Then there are extreme temperatures, dust, moisture, and electrical interference, which can seriously affect these parts. So, high-quality adapters, therefore, are designed for industrial applications and have a much higher durability factor in order to ensure reliable connections and long-term performance.

The Role of Adapters in Ensuring Seamless Communication

Adapters play a crucial role in modern automation systems that allow communication to take place smoothly between various components. Such complex networks carry control signals, data, and power transmitted between real-time devices. These reliable adapters ensure that there is smooth communication between sensors, controllers, and other automation equipment, thus enabling the overall efficiency of the system.

An industrial network is utilized for communication of data between devices, and a lapse in communication for just a moment could impact an entire process. Adapters are quite crucial in this regard and ensure that those lines of communication are intact, thereby preventing any scope for downtime and ensuring the systems of automation work at the maximum levels of functioning.

Ensuring Reliable and Efficient Data Transfer

Adapters are really important to industries requiring precision and accuracy, such as manufacture settings where sensor data is reviewed in regard to the temperature, pressure, and the speed at which manufacturing processes are taking place. The sensors forward the information received to the programmable logic controllers, which by this information alter the machinery or manufacturing processes.

A broken adapter may damage the connection between a sensor and a PLC. Such breakdown can pose problems on the automation system such as wrong data, wrong processing, or safety risks. Top-of-the-line adapters will pass along the data accordingly and maintain the smooth flow for automation systems across fields.

Adapters in Harsh Industrial Environments

Industrial applications require adapters to be robust enough to handle tough environments. Normally, in industrial environments, components withstand extreme temperatures, mechanical stress, and EMC. Indeed, this is often the case in industries that range from mining, automotive, aerospace, or even petrochemical plants, where rugged conditions are part of the normal occurrence of day-to-day operations.

High-quality cables and adapters are designed to withstand extreme conditions while sustaining reliable connections that afford uninterrupted supply to industrial automation systems. They ensure that the operation does not fail but with minimal occurrences of accidents, malfunctions, or interruption in production.

Extending the Lifespan of Automation Systems

One of the main advantages of usings is reliable adapter that they would also help to lengthen the lifespan of the automation system. This occurs because adapters reduce wear on their parts due to secure and stable connections among the various devices. The breakdowns would be minimal, and they also save on maintenance needs.

The selection of the right adapter for an application will ensure that the best performance of the system as a whole is accomplished. Adapters, which meet industry standards, and are appropriate to the specification requirements of the automation system in question, should endure the demands of a given environment with long-term reliability and minimize potential problems.

Enhancing Operational Efficiency with Adapters

It is efficiency that pushes the high rise of most developments in industrial automation. Proper adapters ensure reliability in systems and increase productivity. The adapter has primarily served to deliver proper connectivity, along with real-time data transmission, with the aim of the proper operation of industries.

For example, it may be a fast production plant, where the performance of the system is highly dependent on the speed of information transmission between various devices: sensors, controllers, and actuators. If such communication is somehow slowed down or interrupted at any point, stoppages at the production line are unavoidable. By not taking such action, dependable adapters, which guard against interrupted communication between devices and ensure less rugged processes and fewer durations of production, have undoubtedly been affected.

Adapters and Industrial Networking

Adapters connect the various parts of an automation system. These adapters allow data to flow between devices and make sure all elements of the network contribute toward the goal of network creation with maximum efficiency. Industrial process networking is likely going to be more complex and automated than ever, so there should be a need for high-reliability industrial networking equipment.

Adapters applied for use in industrial networking have to be resistant to questions of high data rates, resist electrical noise, and withstand physical impacts of the environment. They are compatible with the widest range of industrial automation systems and function where a compromise between performance and strength is required.

Choosing the Right Adapters for Industrial Applications

Different factors must be considered in choosing industrial adapters. Some of these are as follows:

- Compatibility: The adaptor being chosen must be compatible with other parts within the system, like the cables, connectors, and devices.

- Environmental Conditions: Extrapolate to some degree the severity of the industrial environment and pick adapters that can withstand these conditions temperature extremes, moisture, etc., EMC.

- Data Transfer Requirements: Once again, depending upon the type of application, an adapter must be able to support the required data transfer rates and power delivery.

- Long Term Durability and Longevity: Quality Adapters should have a good and long-lasting durability and longevity to minimize downtime and maintenance costs; so choose high-quality adapters which are built to last and provide reliable performance over time.

The Growing Need for Reliable Adapters in Modern Automation Systems

Hence, as the face of industrial automation is changing, the demand for reliable adapters is growing. Modern automation systems involve increasing complexity in terms of the number of devices, control systems, and communication protocols. With such sophistication, reliable adapters ensure smooth operations, thus boosting efficiency.

The automation industry now drifts to the Internet of Things where devices are connected, and will converse in real-time. Reliable adapters will make it possible for industrial systems to work more efficiently with high precision.

Adapters would be missing in the system of industrial automation if adapters were not there. They help to transfer data in real time among various devices, thus enabling communication to be carried out without any disruption. They are components that add to the efficacy and reliability of an automation system as a whole. Adapters play a very key role in industrial automation systems, as the complexity of automation solutions increases and a lot of requirements need to be fulfilled by the adapters.

The business can avoid downtime, extend the life of their systems, and increase productivity by opting for the right adapters for specific applications. Simply put, the role played by reliable adapters in industrial automation is non-replaceable. Thus, these minor elements are of great importance to modern automation systems, allowing many industries to run smoothly and efficiently.

Validate your login

Sign In

Create New Account