In a world of marine automation, the safety and efficiency of onboard systems determine smooth performance for vessels. Components like oil mist detectors are essential in maintaining the operational safety by detecting oil mist in the engine room, which is hazardous if not detected. This blog would cover why oil mist detectors in marine automation are crucial, how it is workable, what are the advantages, and why there is a need to select an effective OMD for the marine operators.

What is an Oil Mist Detector?

An oil mist detector is an added safety device to be installed in ships and vessels; this detector will detect the presence of oil mist in the engine room or machinery spaces. It is primarily because of oil mist, which results from other causes like hot temperature or friction. It ordinarily originates from machinery or engines. The air atmosphere can be highly dangerous when this type of mist forms because it tends to have a predisposition to fires or explosions. The usage of OMDs assists in the detection of oil particles; thus, alerting the crew to make proper movements before the situation may become a risky move.

How Do Oil Mist Detectors Function?

Oil mist detectors use sensors that can detect even the smallest droplets of oil suspending in the air. These sensors are typically utilized by either the application of light-scattering technology or infrared sensors for detecting oil mist present in the air. Because of this, once the oil-mist particles pass over the sensor, the measured value would, in turn, be the amount of scattered light for the light-scattering method and infrared light absorbed by the oil mist for infrared sensors.

If the oil mist concentration builds up to a certain extent, then it alarms the crew, meaning that it becomes dangerous. Thus, the crew will immediately take action by either stopping some machinery that may be affected or by ventilating the area such that there will be no more accumulation of the oil mist and the danger that may cause possible fire or explosion.

Why Do Oil Mist Detectors Play a Key Role for Marine Automation?

1. Fire Prevention

Fire prevention becomes one of the main reasons oil mist detectors gain an application in marine automation. Oil and fuel are gulped down in amazing quantities inside an engine room of a ship and such room is considered to be at high risk because the substances contain very easily able to lead to explosions if they collect as their mist in air. If that mist ignites by some spark or a source of heat, that can lead to a gigantic fire.

OMD allows the crew to take pre-emptive measures before the situation gets worse in detecting oil mist. This early warning mechanism prevents hazardous fires, probably causing too much destruction, loss of life, and damage to the environment.

2. Apparatus Protection

Beyond fire protection, oil mist detectors play a critical protective function about onboard machinery equipment. Accidental accumulation of oil mist will lead to corrosion and wear out of the machines and components, thereby shortening the life of expensive marine equipment. Early detection and rectification of oil mist issues ensure that machinery is operated in an efficient and reliable manner with less risk of expensive repairs and losses in terms of downtime.

3. Compliance of Safety Standards

Human life, particularly the crew and passengers of such businesses, and the marine environment are strictly controlled by safety rules that regulate maritime businesses. Oil mist detectors are usually compliant with a number of international standards, such as the International Maritime Organization (IMO) regulations in keeping afloat vessels that navigate the seas. Reliable OMDs allow operators to comply with these regulations and thus avoid fines and penalties while the vessel complies with required safety standards.

4. Energy Efficiency

Oil mist detectors can make the vessel to be energy efficient if well utilized. Effective early detection and mitigation of issues associated with oil mist means that machinery works efficiently, reduces fuel consumption, lowers emission levels, and saves costs in operating; therefore, in the long term, the vessel is environmentally friendly and cost-effective.

5. Crew Safety and Well-being

First of all, the safety of the crew comes first on any ship. Oil mist detectors raise the overall level of crew security because they inform their crew in time about dangerous situations and provide them with the chance to react on time by excluding the risk of possible injury or even death by consequences of accidents with oil mist. Moreover, a safe working environment inspires people with pride for their work and high productivity.

Key Features to Watch Out in a Reliable Oil Mist Detector

While choosing an oil mist detector for marine automation, there are several features worth considering to ensure reliability and performance. Here are some key aspects to pay heed to:

1. Accuracy and Sensitivity:A good oil mist detector must be able to detect small amounts of oil mist accurately. Thus, it should have high sensitivity toward the detection of very low concentrations of oil mist before they become a problem in the cabinet. High sensitivity ensures the device gives early warnings, thereby giving the crew ample time to take action.

2. Durability:Marine environments are harsh, and hence the equipment used onboard has to be withstanding all such conditions which may lead to high humidity, saltwater contact, and vibrations. Thus an oil mist detector that has been specifically designed for the marine environment with the endurance of withstanding the tough marine conditions without degrading their performance should be used.

3. Ease of integration: It should be directly interlinked with the automation system that is already installed in the vessel. Hence, when a detector issues an alert, it transmits information to the control systems and crew members. A very well-integrated OMD can also be monitored from a distance allowing operators to be abreast of situations even while they are not in the engine room.

4. Maintenance and Calibration: All the oil mist detectors require maintenance and calibration. Choose one that is easy to maintain and calibrate with user-friendly instructions that the crew can understand. Self-calibrating some of the OMDs have minimized the amount of frequent manual intervention.

5. Alarm System: The mist detector oil needs an effective alarm system that will notify the crew of probable hazards in real time. The alarm should be loud enough to be audible in a noisy engine room and also capable of conveying the magnitude of the problem through visual indicators such as flashing lights or digital displays.

6. International Standards Conformity: The oil mist detector must be compliant with international standards, possibly functioning under the conventions set forth by the International Maritime Organization. Following these international standards means that it is probably a reliable and accurate OMD in favor of those approved for use on marine vessels.

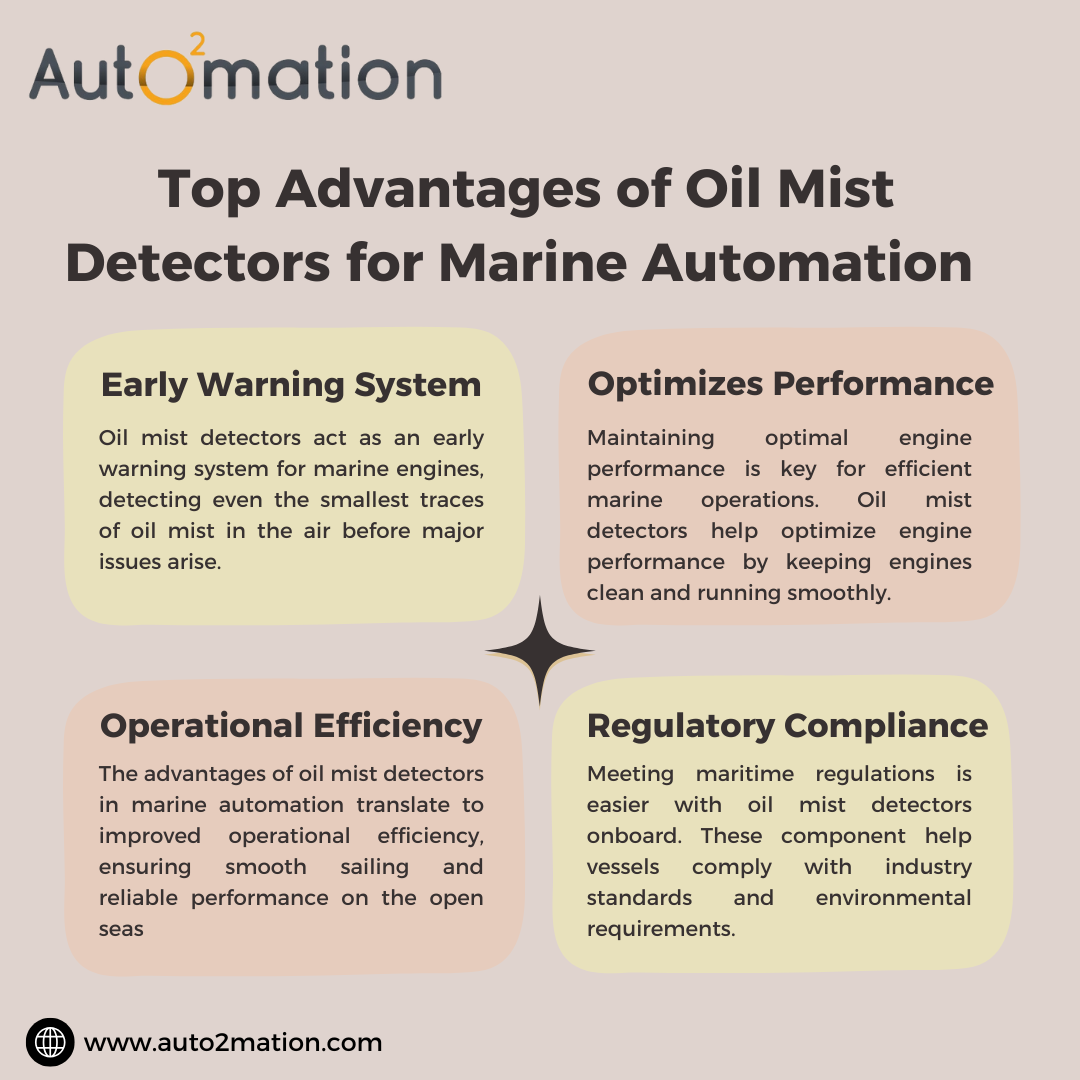

Benefits of Having Reliable Oil Mist Detectors in Marine Automation

1. Safety: Oil mist detectors have their advantage in ensuring safety during operation. The equipment detects oil mist early, preventing fires and explosion and damage to machinery and thus making a safer environment for the crew and the vessel.

2. Cost Savings: Preventing accidents and damage to equipment saves money in the long run. Costs to repair machinery or deal with the effects after a fire are exponentially higher than to install a trustable oil mist detector. Moreover, effective efficiency of equipment and reduced time out lowers the operations costs.

3. Operating Efficiency: Oil mist detectors thus contribute toward the sleek and efficient use of marine automation systems. The machines are guaranteed to be free from oil mist deposits, and hence, they can run at optimum performance while reducing energy consumption and overall efficiency.

4. Compliance with Regulation: With such an oil mist detector, vessels avoid fines and penalties for not adhering to safety regulations. What is more, it puts a marker on the dedication of the crew towards issues of safety and environmental protection concerns-a factor that is gaining momentum within the maritime sector.

5. Improvement of the Crew's Confidence: An efficient oil mist detector can, therefore, create a situation where the crew feels that they are working in a safe area. They can thus focus on their work without constant concerns over the safety issues; they can understand the early warning provided by an OMD regarding potential hazards.

Thus, reliable oil mist detectors in the marine automation are crucial elements of maintaining the safety, efficiency, and longevity of ship machinery and systems. They prevent danger from fires as well as damaging equipment without costly downtime. They also enhance compliance with regulation, reduce operational costs, and promote a safer working environment for the crew. Thus, the right oil mist detector for an enterprise is one that offers reliable and accurate detection with durable equipment which may withstand the large marine environment. An investment in the right OMD will protect your vessel and crew just as much as ensuring long-term operation success and efficiency. Oil mist detection as a priority for marine automation may indeed be a reassurance towards safer and more efficient vessels for operators who would live by international safety standards.

Validate your login

Sign In

Create New Account