Optimizing automation processes in the fast-paced industrial world is a crucial step toward achieving efficiency, reducing downtime, and improving overall system performance. Among the critical components that can contribute to optimization in significant ways are smart I/O modules. Smart I/O modules streamline communication between various devices and systems in an industrial automation setup, thereby ensuring smooth and reliable operations. In this blog, we are going to talk about how smart I/O modules optimize industrial automation, the benefits of using them, and how to select the right ones for your needs.

What are I/O Modules?

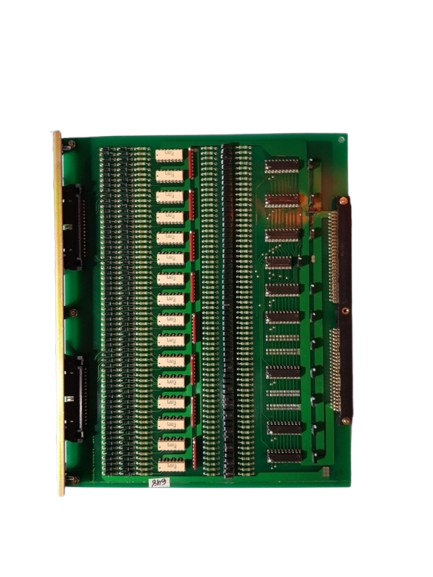

I/O modules represent an interface of hardware devices, such as sensors, actuators, controllers, etc. to a central control system that in most cases either represents a PLC or Distributed Control System of an industrial automation system. The basic role of I/O modules is to pass data from field devices such as sensors to the control system and vice versa for the purpose of ensuring real-time monitoring and control of industrial processes.

Two principal classes exist regarding the type of modules being utilized for I/O purposes. First, digital I/O modules are utilized to control signals that are either ON or OFF, 1 or 0, thus having ON/OFF applications on the board where push buttons, limit switches, or digital sensors take place. Second, there are analog I/O modules, which handle continuous signals, such as temperature, pressure, or flow. Smart I/O modules integrate intelligence in these components, provide means for real-time processing of data, communication, and diagnostics etc. Moreover, with Industry 4.0 and IoT, smart I/O modules have become more advanced as well as added more value in industrial automation systems.

Major advantages of smart I/O modules

- Efficiency: Smart I/O modules can make industrial automation systems function better by allowing them to process data faster and, therefore, communicate at better rates. The advantages of these modules are the ability to process data at the source close to the device with much less burden left at the central controller to minimize delay in response times. When a sensor reports that it has an abnormal condition, a smart I/O module can alert the control system or request to take immediate corrective actions when an unfavorable error presents.

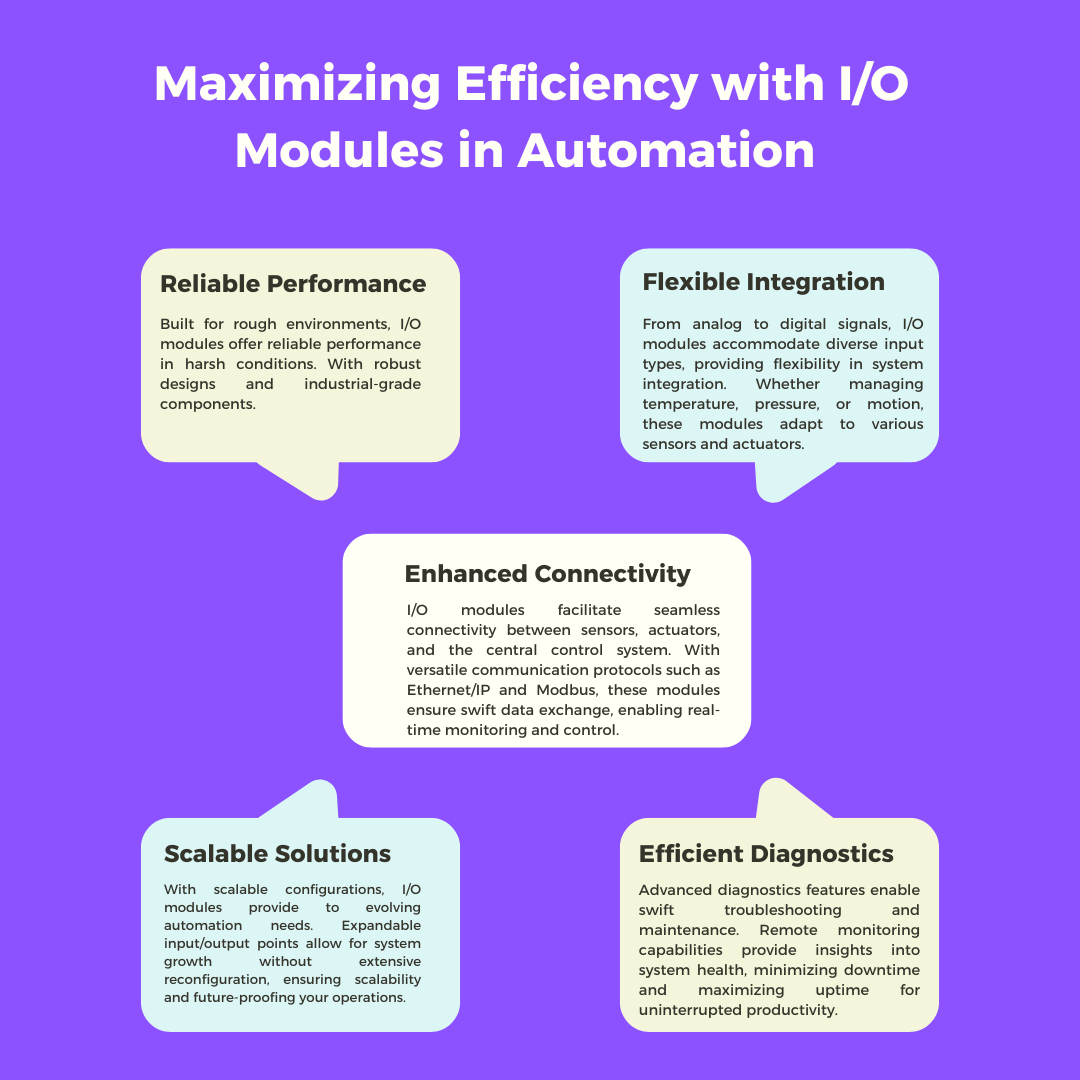

- Improved Connectivity: Current industrial environment is heterogeneously populated with devices and systems presented by various manufacturers. SmI/O modules are so set to be highly compatible with many communication protocols which fall among them include Modbus, Profibus, Ethernet/IP, just to name but a few. This diversity means excellent integration into already available automation systems enhancing the connectivity of diverse hardware and software devices. Accordingly, the operation tends to be better harmonized whereas data exchange will also come out as easier hence high performance.

- Real-Time Data Access and Monitoring: Smart I/O modules will provide the ability to read data in real time such that it becomes easy for the operators to monitor such critical process variables as temperature, pressure, and flow. Real-time monitoring will enable early tracking of problems such that good decisions will be forthcoming in due course. Diagnostics and status indicators come as an inbuilt feature in these modules that help maintenance teams identify any possible problems before they result into downtime or equipment failure.

- Less Downtime and Maintenance: Smart I/O modules provide predictive maintenance. A large number of inbuilt diagnostic capabilities are integrated into these modules that can monitor the health of the connected devices and indicate where a potential failure might be possible, thus making the operators or maintenance personnel know. This can be seen to reduce unplanned downtime and minimize the costs of maintaining, hence making your automation system more reliable and economical in the long run.

- Flexibility and Scalability: Industrial automation systems commonly require flexibility toward the change in requirements. Smart I/O modules provide great flexibility as well as scalability. For example, you may want to include more sensors or start controlling some additional processes or include some scale to your system as per increased production demands; with smart I/O modules, these are easily expandable or reconfigurable. Flexibility, therefore, helps businesses adapt quickly towards a change in production processes that might occur without requiring a totally changed system.

- Better Data Security: One of the major concerns in an industrial automation system, where many devices will be coming connected, is security. Advanced encryption and authentication, with secure protocols of communication, should ensure safety against cyber threats by data transferred between the devices and the systems. This added security will prevent unauthorised access while preserving the integrity of your industrial processes.

- Edge Computing Capabilities: Increasing requirements in real-time processing increase the growth of industrial automation with an edge computing platform. Edge-computing-based smart I/O modules consist of processing data locally at the origin with the capability of not necessarily sending all the information to the central control system. Such an activity not only benefits the reduction of latency but is also useful for the reliability of the system because of reduced data transfers over the network. By doing edge processing of the data, these modules can take simple control functions and decrease the load on the central control system so that responses can come fast.

How Smart I/O Modules Improve Automation Systems

- Seamless Device Integration: One of the major ways smart I/O modules optimize automation systems is through smooth integration of a variety of devices. In industrial environments, there will be various equipment from different manufacturers, each with its communication protocol. Smart I/O modules bridge this gap by supporting various communication standards, which means that it becomes easier to integrate new devices into an existing system. Such interoperability enhances the overall efficiency and performance of the automation system.

- Data acquisition and analysis: Smart I/O modules collect data from sensors and field devices, giving insight into the performance of your industrial processes. They could track variables such as temperature, pressure, speed, etc., and send this data to a central control system or to the cloud for analysis. This information enables operators to identify trends, spot inefficiencies, and optimize the processes to reduce energy consumption, increase production rates, or enhance product quality.

- Advanced Diagnostics and Troubleshooting: Traditional I/O modules can only send simple data. Therefore, troubleshooting is really tough. Smart I/O modules are designed with advanced diagnostics capabilities, and it can find any problem that may have occurred in specific devices or systems. These modules give comprehensive status updates, error codes, and even recommendations for correction actions. This diagnostic ability helps the operators and the maintenance crew easily trace problems and solve them promptly without wasting much time, and, thus, the system works in good order with less downtime.

- Energy Efficiency: The other one is that smart I/O modules help the user optimize energy consumption, which is one of the big hurdles to industrial operations. Modules track energy usage with parameters such as voltage, current, and the use of power. It may be able to identify inefficiency or any form of anomaly in consuming energy. This will help businesses consume less energy, cut costs, and hence obtain sustainability goals.

- Programmable Control: Smart I/O modules allow for the possibility of highly customized control strategies. Operators can set up parameters, thresholds, and actions based on real-time data to ensure that the system responds to changing conditions. The flexibility this allows businesses to fine-tune their automation systems so that they can optimally produce and respond to new requirements without costly upgrades of the system.

Selecting the Right Smart I/O Modules

When choosing smart I/O modules for your industrial automation system, consider the following factors:

- Compatibility: The I/O modules should be compatible with your existing systems, including communication protocols and device types. The modules should support the specific standards used by your equipment.

- Scalability: Choose modules that will expand easily with your system growth. Make sure to look for modules that can accommodate additional inputs and outputs as your automation needs change.

- Reliability: Industrial systems require reliable solutions, so make sure to choose smart I/O modules from manufacturers known for making high-quality, rugged components capable of withstanding harsh environments.

- Security: Issues with the cyber-security of industrial systems are rising to prominence; therefore, security needs to be at the top in the I/O modules which provide more secure encryption and safe channels.

- Edge Computing Capability: An edge computing capable smart I/O module needs to be opted for when the process data has to be processed in real time or if the delay in data processing is unacceptable.

- Diagnostics and Monitoring: A good I/O module shall have diagnostics that will display real-time feedback about how the system is doing its health and performance as well as problems that are detected.

Smart I/O modules are one of the most effective means of optimizing industrial automation systems. They offer real-time access to data, enhanced connectivity, predictive maintenance, and advanced diagnostic features-all of which play a great role in enhancing efficiency, reducing downtime, and generally improving the overall system performance. Whether it is an upgrading or designing of an existing automation system, smart I/O modules add up to the convenience of operations and save time. Hence, due to the flexibility, scalability, and more advanced features in a smart I/O module in industrial businesses, they always manage to get ahead in today's competitive marketplace.

Validate your login

Sign In

Create New Account