Industrial automation has made a marked difference in the way industries are run, especially in manufacturing, logistics, and supply chain management. On this list, industrial automation scanners feature importantly as some of the components used to enhance efficiency, accuracy, and productivity. From barcode scanner to complex RFID systems, these devices automate vital processes, reducing errors and improving operational visibility. This blog will explores the issue of how industrial automation scanners improve productivity and its influence on different sectors.

What are industrial automation scanners?

Industrial automation scanners are hardware devices that capture, process, and transmit data in automation environments. Examples of such scanners include barcode scanning technology, QR code readers, as well as RFID scanning. They're broadly used to monitor inventory, to fill orders, and also to check the quality. Such automation scanners in a business integrate the automation systems to ensure effortless workflows with minimal human intervention.

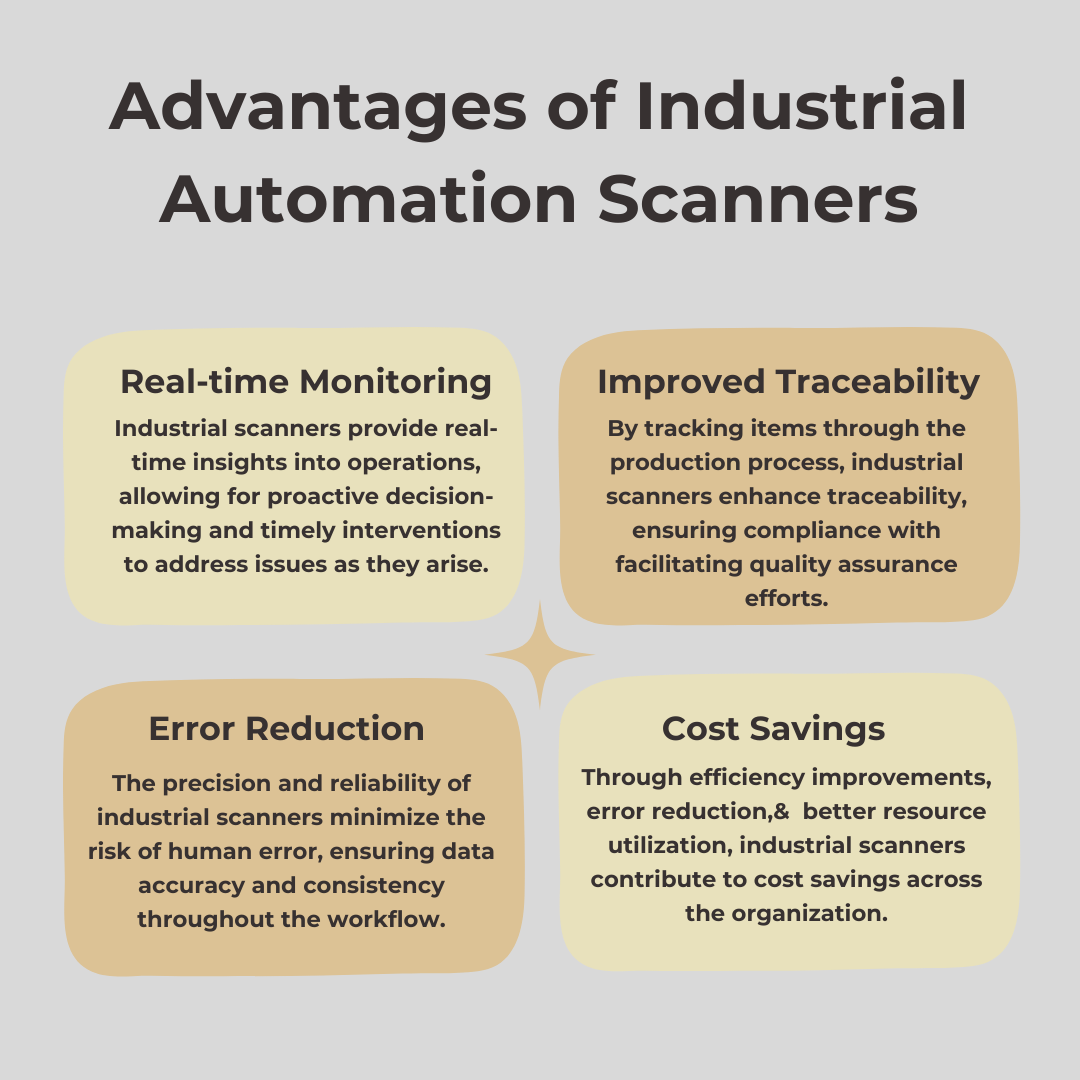

Important Advantages of Industrial Automation Scanners

- Data Accuracy: Data entry has room for human error. Businesses will incur mistakes when done manually. The risk is avoided by automation scanners since they are very accurate in data capture. From reading barcodes on the product to reading RFID tags, accuracy is ensured for these scanners to help businesses avoid errors in record-keeping and make informed decisions.

- Faster Operations: Industrial scanners make several processes much faster including counting of the inventory, picking orders and labeling products. For example, in the warehouses, instead of scanning many items under the barcode scanners, workers cut down waiting time as well as order processing accelerates under the facility of barcode scanners.

- Real-time Visibility: The automation scanner will report in real time on how much stock is available, how far along a production run is, and shipment. This allows businesses to get the most use out of all resources, prevent stockouts, and meet customers' needs faster.

- Scalability: Industrial automation scanners can easily scale with business growth. If the operations grow, then more scanners can be added to the system for the sake of efficiency.

Types of Industrial Automation Scanners

1. Barcode Scanners

The most widely used industrial automation scanner is the barcode scanner. Barcode scannersread linear barcodes on products, packaging, and pallets. These scanners are fast, reliable, and easy to integrate into automation systems. Most common types include handheld scanners, fixed-mount scanners, and wearable scanners.

2. RFID Scanners

It uses RFID scanners that scan and track items with much accuracy by radio frequency signals. Scanning bulk items at a time can be more preferred using barcode scanners since scanning bulk items does not need any direct line of sight.

3. 2D and QR code readers

They can read 2D barcodes or QR codes that contain higher information than the usual ones. They can use this in industries where specific information about a certain commodity needs to be accessed. It includes healthcare and retail.

4. Picture-Based Scanners

The image-based scanners rely on high-tech imaging. They read the information of a barcode or QR code in very detailed form with maximum accuracy and can even read a damaged or a poorly printed code.

Application of Industrial Automation Scanners

- Warehouse Management: Scanners automate and speed up processes such as warehouse inventory management, order picking, and shipping. An RFID scanner can directly update the inventory records, eliminating the need to physically check the stock after some time.

- Manufacturing: Quality control is done and the production stages followed. Automation scanners also trace products' movement to identify where the mistake lies, whether defective products, among others. This can identify and prevent defective products from reaching the customers. Scanners enable real-time tracking of shipments. This minimizes delays and ensures satisfaction of customers. RFID scanners are particularly useful in tracking goods over long supply chains.

- Retail: Retailers use scanners for inventory management, point-of-sale tracking, and automated checkout. QR code readers also help with contactless payments, making the purchasing process easier.

- Healthcare: Automation scanners in healthcare enable the accurate identification of patients, medical supplies, and laboratory samples. Scanners will give high returns by reducing errors and enhanced patient safety.

How Scanners Improve Productivity in Industrial Automation

1. Improved Inventory Control

Proper management of inventory is very crucial to productivity. Automated scanners make it easier because they can give real-time accurate data about the stock levels. For instance, an RFID scanner can read hundreds of tags in a second. This will save much time and effort as compared to counting manually.

2. Improving Order Fulfillment

E-commerce and retail companies have constantly employed barcode readers in filling orders quickly and on time to boost the satisfaction of the customers. By scanning the item, the right one is selected so that it's picked, packed, and sent correctly. This entire process eliminates error or delay.

3. Facilitating Quality Control

Quality control in manufacturing is quite significant. Scanners automation of use verifies all details in each step of manufacturing so that the end products are high quality. This reduces wastage and increases the value of the building brand.

4. Facilitates Predictive Maintenance

In an industrial setting, RFID scanners can monitor the condition of machines and equipment. Predictive maintenance using this data will minimize downtime and ensure continuous operation.

Top Features to Look for in Industrial Automation Scanners

When selecting a scanner for your automation requirements, look for the following features:

- Durability: Industrial settings can be quite rough, so scanners should be robust and capable of withstanding extreme conditions.

- Connectivity: There should be available wireless connectivity such as Bluetooth or Wi-Fi to integrate scanners into automation systems.

- Scanning Speed: High-speed scanners increase the productivity of the workers because it takes less time in data capture.

- Ease of Use: Easy to use and ergonomic design of the scanners increases the productivity of the workers.

- Data Storage: There are some onboard data storage facility available in the scanners that assist in performing offline functions.

Future of Industrial Automation Scanners

Industrial automation scanners of the future promise much with AI, ML, and IoT. Expect these to come:

- AI-Driven Scanners: The scanning of data shall be faster in AI-driven scanners and will be beneficial for businesses through actionable insights.

- IoT Scanners: IoT networks will keep on developing. Devices shall start communicating with one another for the maximum automation in scanning.

- High-End Imaging: They shall scan and decode the harshest code by this new generation imaging technology.

- Miniaturization: Miniaturize this scanner and have it become compact enough to fit the most minute space in any industry.

Industrial automation scanners are very important in the modern industries as they help increase productivity and efficiency. They save errors, time, and give room for optimal workflow since they handle critical processes such as inventory management, order fulfillment, and quality control. With the development of technologies, the place of automation scanners will only increase to offer businesses even better opportunities to heighten their operations.

Validate your login

Sign In

Create New Account